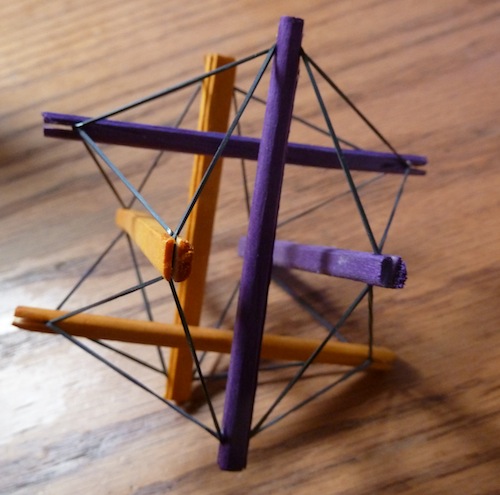

Putting notches in dowels by hand

I am preparing a workshop where we will make tensegrities. These beautiful little mathematical decorations require (the way I make them) dowels with notches in the ends. I made a special saw to notch the dowels on the spot, instead of notching a bunch of them in advance. I just hope that people will be able to use them!

Here is a demo of the saw:

And here is an instructable:

http://www.instructables.com/id/A-saw-for-putting-notches-in-the-ends-of-dowels-b/

Here is the text from the same instructable:

This is the perfect tool if your crafts require that you notch the ends of a lot of dowels, but you don't have a band saw, or you don't want to be running back and forth to the ban saw. The cuts it makes are clean, and if you are careful with the measurements, you'll be notching the middle of the dowels.

One rule that I follow is:

Don't measure anything when you can square it up as you go.

The other rule is:

Don't measure anything twice if you can easily toss it away and do it again.

I think the pictures are somewhat self explanatory, so I haven't broken it down into steps.

The materials are:

-a thick bolt with a flat or round head (the type that go into wood)

-a long bolt. this will adjust the tension on the saw blade. see pictures for nuts and washers

-one thick washer which will connect to the saw blade.

-a coping saw blade (google this one, it's those extremely thin blades.

-4 thin bolts

-4 "thick" washers. These are your spacers around the saw blade

-some scrap wood, including a 2x4.

A drill, dremel tool and cut off disks is nearly indispensable here. If you don't have one and you are into this stuff, get one right away. I recommend grabbing a no name drill, but brand name (dremmel) bits. that way you don't care about burning out a $15 drill, but you have good bits to work with.

1. Put that thick bolt in and hammer it flat on the bottom so your saw lies flat.

2. Cut the bolt down to the right length.

3. Notch the bolt so the saw blade sits in it.

4. Prepare the tension assembly and screw it on wherever the saw blade comes to.

5. Cut a notch in the thick washer for the blade to sit in.

6. Put tension on the blade until it twangs nicely.

7. Prepare the guides that will keep the dowel centered on the blade.

8. Use the thick washers for spacers. Note that you can make an adjustable version of this thing, but I didn't need one.

9. Bottom bolts use the spacers, the top two bolts are just so the dowel doesn't run off the end of the saw.

Finally: To notch a dowel use a block of wood with a hole to hold it. The dowel should stick out the same amount as the depth of the desired notch. Enjoy your notching!